Selmax offers technical consultation at the earliest stages of product design. We have quite literally, started several customer projects from designs on the back of napkins. We work closely with our customers to define the requirements of the finished product – physical dimensions, structural supports, custom engraving, color, texture and finishing.

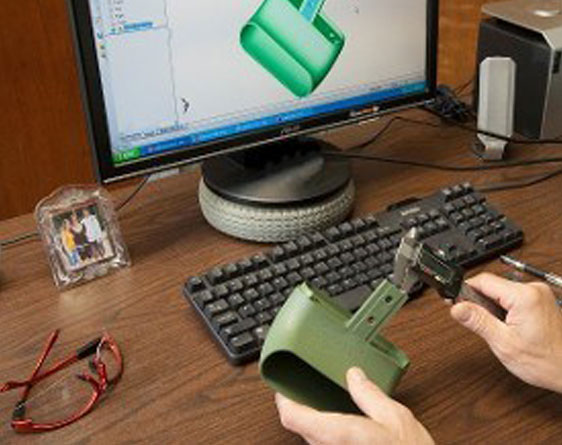

Using SOLIDWORKS Computer-Aided Design (CAD) tools, we can assist our customers in designing their plastic products to their specifications. We have years of mold making and production molding experience. Allow us to use our problem-solving expertise to optimize your design for product appearance, performance and manufacturability while staying within your budgetary constraints.

If you already have a completed design, we can accept all common CAD file formats and can move quickly to the prototyping or mold development phase.

Many of our customers also have very stringent color-matching and aesthetic requirements. We have hundreds of colors available and a very tightly-controlled quality process to satisfy any color specifications. We use X-Rite Color Management equipment and software for precision color control.

Selmax has established strong long-term relationships with our material and colorant suppliers to provide the right expertise for product design. We have experience with many plastic material types. Most common include:

- ABS

- Polypropylene

- Nylon

- Polycarbonate

- Polyethylene (HD/LD)

- Polystyrene

- Polyurethane

- Acetal

- ASA

- Grivory

- TPE/TPU/TPV